Top-tier programs for welding education offer comprehensive training, combining theoretical knowledge with hands-on experience. These institutions equip students with the skills and certifications necessary for successful careers in various welding sectors, from construction and manufacturing to specialized fields like underwater welding. Graduates often possess proficiency in diverse welding techniques, safety protocols, blueprint reading, and metal fabrication.

Skilled welders are in high demand across numerous industries. Choosing a high-quality educational program significantly impacts career prospects, earning potential, and long-term professional success. Historically, welding has played a crucial role in infrastructure development and technological advancement, and its importance continues to grow as industries evolve. Reputable training institutions contribute to this evolution by producing qualified professionals who meet industry standards and drive innovation.

The following sections will delve into the key factors to consider when selecting a welding program, including curriculum, accreditation, faculty expertise, facilities, and career support services. Furthermore, resources for researching and comparing top programs will be provided, along with insights into emerging trends and specializations within the welding field.

Tips for Selecting a Top-Tier Welding Training Program

Choosing the right welding education is crucial for career success. These tips offer guidance for prospective students seeking high-quality training programs.

Tip 1: Research Program Accreditation: Ensure the program holds accreditation from recognized welding organizations, signifying adherence to industry standards and quality education.

Tip 2: Evaluate Curriculum Breadth: Look for programs covering a range of welding processes, including SMAW, GMAW, GTAW, and FCAW, to ensure versatility and adaptability in the job market.

Tip 3: Assess Faculty Expertise: Experienced instructors with industry credentials provide valuable practical knowledge and mentorship.

Tip 4: Inspect Facilities and Equipment: Modern, well-maintained equipment and ample workspace are essential for effective hands-on learning.

Tip 5: Investigate Career Services: Robust career support, including job placement assistance and resume workshops, helps graduates transition smoothly into the workforce.

Tip 6: Consider Program Length and Format: Choose a program that aligns with individual learning styles and career goals, whether a short-term certificate or a comprehensive associate degree.

Tip 7: Explore Financial Aid Options: Investigate available scholarships, grants, and loan programs to manage educational expenses effectively.

Selecting a welding training program requires careful consideration of various factors. By following these tips, prospective students can make informed decisions that contribute to long-term career success.

The subsequent section will provide a concluding overview of the importance of quality welding education and its impact on the welding profession.

1. Accreditation

Accreditation plays a vital role in distinguishing high-quality welding training programs. Reputable accrediting bodies, such as the American Welding Society (AWS), establish rigorous standards for curriculum, faculty qualifications, safety practices, and facilities. Programs achieving accreditation demonstrate a commitment to providing comprehensive education that aligns with industry demands. This benefits students by ensuring they receive training that meets recognized professional benchmarks, increasing their employability and potential for career advancement. For instance, employers often prioritize candidates who have graduated from accredited programs, recognizing the value of standardized, high-quality training.

Choosing an accredited program offers several practical advantages. Graduates from accredited schools may be eligible for certain certifications more easily, as their education already meets prerequisite requirements. Moreover, some employers may offer higher starting salaries to graduates of accredited programs. Accreditation also signifies that the program undergoes regular evaluation and improvement, ensuring its curriculum remains current with evolving industry technologies and practices. This continuous improvement benefits both students and the welding profession as a whole by maintaining high standards of training and competency.

In summary, accreditation serves as a crucial indicator of quality in welding education. It provides assurance to prospective students, employers, and the industry that a program meets established standards of excellence. While factors like curriculum, faculty, and facilities contribute to a program’s overall quality, accreditation provides a valuable framework for evaluation and a benchmark for recognizing top-tier welding trade schools. Therefore, prioritizing accredited programs is a prudent strategy for individuals seeking a successful and rewarding welding career.

2. Curriculum

A robust curriculum is a cornerstone of any best welding trade school. It directly impacts the skills and knowledge graduates acquire, influencing their career readiness and long-term success. A well-designed curriculum seamlessly blends theoretical instruction with extensive hands-on training, preparing students for the diverse challenges and opportunities within the welding profession.

- Welding Processes

Comprehensive coverage of various welding processes, such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW), is essential. Exposure to these diverse techniques allows graduates to adapt to different job requirements and industries. For example, training in GTAW might be crucial for precision welding in aerospace applications, while SMAW skills are often required in structural steel erection.

- Blueprint Reading and Interpretation

Understanding technical drawings and blueprints is fundamental for welders. A strong curriculum incorporates detailed instruction in blueprint reading, enabling students to accurately interpret welding symbols, specifications, and joint designs. This skill is critical for ensuring the structural integrity and quality of welded components in various construction and manufacturing projects.

- Safety and Health Procedures

Welding involves inherent risks, necessitating a thorough understanding of safety protocols. Best welding trade schools prioritize safety training, covering topics such as personal protective equipment (PPE), fire prevention, hazard recognition, and emergency procedures. This emphasis on safety equips graduates to work responsibly and minimize workplace accidents.

- Metallurgy and Materials Science

Knowledge of metal properties, heat treatments, and welding metallurgy is crucial for producing high-quality welds. Top programs incorporate elements of materials science into their curriculum, enabling students to understand how different metals react to heat and stress, informing their welding technique and material selection. This knowledge is particularly important for specialized welding applications, such as those involving exotic alloys or high-strength steels.

These curricular components, when integrated effectively, equip graduates with the comprehensive skillset necessary for success in the demanding and evolving field of welding. A well-rounded curriculum, combined with experienced instructors and modern facilities, distinguishes best welding trade schools and positions graduates for rewarding careers in diverse industries.

3. Faculty Expertise

Instructor expertise significantly distinguishes top welding training programs. Highly qualified instructors, often possessing extensive industry experience and certifications, provide invaluable practical knowledge, mentorship, and real-world insights, enriching the educational experience and preparing students for successful careers.

- Industry Credentials and Certifications

Instructors holding certifications from recognized organizations like the American Welding Society (AWS) or the American Society for Nondestructive Testing (ASNT) demonstrate a mastery of industry standards and best practices. These credentials validate their expertise and ensure students receive training aligned with professional requirements. For example, a Certified Welding Inspector (CWI) on the faculty can provide specialized instruction in weld quality control and inspection techniques.

- Real-World Experience

Faculty with practical experience in diverse welding applications, such as pipeline welding, structural steel fabrication, or aerospace welding, bring valuable real-world perspectives to the classroom. They can share firsthand knowledge of industry challenges, problem-solving strategies, and specialized techniques, enhancing student learning and preparing them for the complexities of the profession. A former underwater welder on the faculty, for example, can provide unique insights into the specialized procedures and safety protocols required for this demanding field.

- Teaching Methodology and Mentorship

Effective instructors possess strong pedagogical skills and a passion for sharing their knowledge. They create engaging learning environments, employing various teaching methods, including demonstrations, hands-on exercises, and real-world case studies. Furthermore, they serve as mentors, providing individualized guidance and support to students throughout their educational journey, fostering both technical skills and professional development.

- Commitment to Continuing Education

The welding field constantly evolves with advancements in technology and techniques. Best welding trade schools employ instructors committed to lifelong learning, who stay abreast of industry trends through continuing education courses, professional development workshops, and active involvement in professional organizations. This commitment ensures that students receive the most up-to-date training and are prepared for the challenges and opportunities of a dynamic industry.

The collective expertise of the faculty significantly impacts the quality and effectiveness of a welding education. Experienced, certified instructors with a passion for teaching provide students with the knowledge, skills, and mentorship necessary to excel in their chosen welding careers. This emphasis on faculty expertise distinguishes best welding trade schools and contributes significantly to student success and industry advancement.

4. Modern Facilities

Best welding trade schools understand that modern facilities are crucial for effective skills development. A well-equipped learning environment directly impacts the quality of education and student preparedness for real-world welding challenges. Modern facilities provide students with access to cutting-edge equipment, mirroring industry standards and preparing them for seamless integration into professional settings. This correlation between modern facilities and best welding trade schools stems from the necessity of hands-on experience with the latest technologies. For example, access to advanced welding simulators allows students to practice diverse techniques in a controlled environment before applying them to real-world projects. Similarly, availability of various welding machines, including GMAW, GTAW, and FCAW equipment, broadens skill sets and caters to diverse career paths. Furthermore, well-maintained ventilation systems and spacious work areas contribute to a safe and productive learning experience, essential aspects of any reputable welding program.

The practical significance of modern facilities extends beyond basic skill acquisition. Students gain familiarity with industry-standard tools and equipment, reducing the learning curve upon employment. Exposure to advanced technologies, such as robotic welding systems or automated cutting machines, prepares graduates for the evolving landscape of the welding profession. For instance, a school equipped with a robotic welding cell allows students to develop skills highly sought after in automated manufacturing environments. Moreover, modern facilities often provide opportunities for specialized training and certifications, further enhancing career prospects. The investment in modern facilities reflects a commitment to providing students with the best possible educational foundation, directly contributing to their success and the advancement of the welding industry.

In conclusion, modern facilities are an integral component of best welding trade schools. They provide the necessary tools and environment for effective skills development, ensuring graduates possess the practical experience and technological proficiency required in today’s welding industry. The investment in modern facilities directly translates into student success, higher employability, and contributions to the ongoing advancement of welding technology. This crucial link between modern infrastructure and quality welding education reinforces the importance of considering facilities as a primary factor when evaluating welding training programs.

5. Career Support

Robust career support services distinguish best welding trade schools, bridging the gap between education and employment. These services are integral to student success, providing crucial resources and guidance for navigating the job market and launching fulfilling careers. Effective career support transforms graduates into competitive candidates, equipped not only with technical skills but also with the professional acumen necessary to thrive in the welding industry.

- Job Placement Assistance

Top welding programs actively facilitate job placement, connecting graduates with potential employers. This may involve maintaining relationships with industry partners, organizing career fairs, and providing personalized job search guidance. For instance, a school might partner with local construction firms or manufacturing companies to offer apprenticeship opportunities or direct employment to qualified graduates. Effective job placement assistance significantly shortens the job search process and ensures graduates find suitable positions aligned with their skills and career goals.

- Resume and Interview Preparation

Crafting a compelling resume and performing well in interviews are critical job search skills. Best welding trade schools offer workshops and individualized coaching to help students develop professional resumes and cover letters that highlight their welding skills and experience. Mock interviews provide valuable practice and feedback, boosting confidence and preparing graduates to effectively present themselves to potential employers. These preparatory services ensure students can effectively articulate their qualifications and make a strong impression during the hiring process.

- Networking Opportunities

Building professional networks is essential for career advancement. Best welding schools facilitate networking opportunities by organizing industry guest speaker events, workshops led by practicing welders, and field trips to welding companies. These activities provide students with valuable connections and insights into different career paths within the welding industry. Networking can lead to mentorship opportunities, internships, and even job offers, expanding career horizons and fostering professional growth.

- Certification Guidance and Support

Obtaining industry-recognized certifications, such as those offered by the American Welding Society (AWS), enhances employability and earning potential. Best welding trade schools guide students through the certification process, providing information on eligibility requirements, exam preparation resources, and testing procedures. Some schools may even offer certification testing on-site, streamlining the process and maximizing student success in achieving professional credentials. This support ensures graduates possess the certifications employers value, increasing their competitiveness in the job market.

Comprehensive career support services are a hallmark of best welding trade schools. These services empower graduates with the tools and resources necessary for a successful job search and career advancement. By providing job placement assistance, resume and interview preparation, networking opportunities, and certification guidance, these institutions demonstrate a commitment to student success beyond the classroom, fostering a smooth transition into the professional welding world and contributing to a skilled and thriving workforce.

6. Industry Connections

Strong industry connections are a defining characteristic of best welding trade schools. These connections represent a symbiotic relationship between educational institutions and the professional welding community, benefiting students, employers, and the industry as a whole. These partnerships provide a crucial link between theoretical learning and practical application, enhancing the educational experience and ensuring graduates possess the skills and knowledge sought after by employers.

Several factors contribute to the significance of industry connections. Partnerships with welding companies, fabrication shops, and construction firms create opportunities for internships, apprenticeships, and job shadowing. These experiences provide students with invaluable real-world exposure, allowing them to apply classroom learning in professional settings, gain practical skills, and build professional networks. For example, an internship with a pipeline construction company could expose a student to specialized welding techniques and safety protocols relevant to that industry sector. Furthermore, industry partners often participate in curriculum development, ensuring program content aligns with current industry needs and technological advancements. This collaboration keeps the curriculum relevant and prepares graduates for the evolving demands of the welding profession. For instance, input from manufacturing companies might lead to the incorporation of robotic welding training into the curriculum, reflecting the growing automation within the industry.

The practical implications of strong industry connections are substantial. Graduates from programs with robust industry ties often experience higher job placement rates and smoother transitions into the workforce. Employers benefit from access to a pool of well-trained, industry-ready graduates, reducing recruitment costs and training time. The welding industry as a whole benefits from a skilled workforce, driving innovation and maintaining high standards of quality and safety. Challenges may include maintaining consistent engagement from industry partners and ensuring equitable access to opportunities for all students. However, the long-term benefits of fostering strong industry connections significantly outweigh these challenges, reinforcing their importance as a key component of best welding trade schools. By prioritizing and cultivating these relationships, welding training programs contribute to the success of their graduates, the growth of the welding industry, and the advancement of welding technology.

Frequently Asked Questions about Top Welding Training Programs

This section addresses common inquiries regarding the selection and evaluation of high-quality welding education programs. Understanding these key aspects assists prospective students in making informed decisions aligned with individual career goals and aspirations within the welding profession.

Question 1: What distinguishes top welding trade schools from other welding training options?

Top programs typically offer comprehensive curricula, AWS accreditation, experienced instructors, modern facilities, strong industry connections, and robust career support services. These factors collectively contribute to a superior educational experience and enhanced career prospects.

Question 2: How does program accreditation impact career opportunities?

Accreditation from recognized organizations like the American Welding Society (AWS) signifies adherence to industry standards and best practices. Employers often prefer graduates from accredited programs, increasing employment opportunities and potential for career advancement.

Question 3: What is the typical duration of a welding training program?

Program length varies depending on the specific credential sought. Certificate programs can range from several months to a year, while associate degree programs typically require two years of study. Short-term specialized courses also exist for specific welding processes or techniques.

Question 4: What career paths are available to graduates of welding trade schools?

Welding offers diverse career options, including structural welding, pipe welding, underwater welding, fabrication, and inspection. Graduates can find employment in construction, manufacturing, aerospace, energy, and other industries.

Question 5: What is the earning potential for welders?

Earning potential varies based on experience, skill level, industry, and location. However, skilled welders, especially those with specialized certifications, can command competitive salaries and benefits.

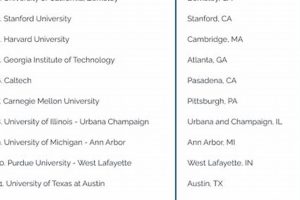

Question 6: How can one research and compare different welding training programs?

Online resources, such as the AWS website and other educational directories, provide information on accredited programs. Visiting schools, attending information sessions, and speaking with current students or alumni offer valuable insights into program quality and student experiences.

Thorough research and consideration of these factors are crucial for selecting a welding training program that aligns with individual career aspirations and maximizes potential for success within the welding profession.

The following section provides a concluding summary of key takeaways and emphasizes the significance of choosing the right welding education for a rewarding career.

Best Welding Trade Schools

Choosing among the best welding trade schools represents a pivotal decision for aspiring welders. This exploration has highlighted the critical components of exceptional welding education, emphasizing the importance of accreditation, comprehensive curricula, experienced faculty, modern facilities, robust career support, and strong industry connections. These elements collectively contribute to a superior training experience, equipping graduates with the skills, knowledge, and professional networks necessary for successful and rewarding careers.

The welding profession offers diverse and evolving career opportunities. A commitment to selecting a high-quality training program provides a strong foundation for navigating this dynamic landscape. Thorough research, careful consideration of program features, and alignment with individual career goals are essential for maximizing the long-term benefits of a welding education and contributing to the ongoing advancement of the welding industry.